Menu

Menu

Updated on Jul 7, 2023 | 10 min read

Ah, the good old days when telephones had those trusty fixed wires! Humans roamed freely without the burden of carrying around a small wire and a brick-like device to charge their tabs, mobile phones, and laptops. But fear not, my fellow Homo sapiens, for this article is not about our freedom or lack thereof. No, no, it is all about that magical act of CHARGING! And not just any charging, mind you. We are diving deep into the realm of ELECTRIC VEHICLE charging. Brace yourselves for a shocking and electrifying adventure!

“The ADAPTER is not a CHARGER.”

Every device in need of a power fix requires a trusty sidekick to store that precious energy. And behold, the superhero of power storage emerges – the mighty battery! This wondrous contraption holds within it the secret recipe of chemical energy, ready to unleash a burst of electrical power when called upon. But hold your horses, my friends, for not only do our beloved gadgets have a battery within, but even the majestic Electric Vehicles (EVs) boast their energy reservoirs.

Now, picture this: the EV’s battery, yearning for a refill, seeks solace in the presence of a brick-like figure. Yes, you heard it right, a brick! But fear not, for in our delightfully twisted world, we humans, and the Original Equipment Manufacturers (OEM) affectionately refer to this brick as a mere “charger.” Little do we know, behind the scenes, the real star of the show flaunts its fancy title as the Electric Vehicle Service Equipment (EVSE). Oh, the secrets they keep! “Don’t believe me? Pick up the charging unit of your nearest device and read what is written on its charger or adapter. Now, who is this unsung hero? It is the one that facilitates the connection between your trusty EV (Electric Vehicle) and the almighty electrical grid. Now that you possess this knowledge, you have the power to impress your companions as a true genius of charging wisdom. Embrace your newfound prowess and let the sparks of engineering humor flow through your veins!”

“Basic POWER Terminology”

Before we delve into the realm of EV charging, let us revisit some concepts from 8th-grade physics.

“Demystifying EV Battery Charging: From Induction to Conduction!”

So, let us unravel the mysteries of charging a battery. The most common, preferred, and recommended method by Original Equipment Manufacturers (OEM) is charging the battery inside the vehicle itself. However, there is another option: charging the battery outside the vehicle. Now, inside the vehicle, we have two ways to charge the battery. One intriguing approach is through wireless technology, known as Induction charging, although it is rare. The more prevalent method is good old-fashioned plugging in through a cable, named Conduction charging.

Charging the battery outside the vehicle is achieved through the process called Battery swapping, which although not yet a widely adopted method, functions based on Conduction Charging principles.

DC Charging vs AC Charging

As batteries are Direct Current (DC) sources, they are not designed to handle Alternating Current (AC) supply for either input or output. This poses a challenge, considering that electricity distribution worldwide is AC.

A crucial component called a rectifier comes into play. The rectifier is responsible for converting the AC supply into DC every time we charge the battery. Its role is to provide rectified power with specific voltage and current limits as prescribed by the OEM for the battery. To further ensure the compatibility of the rectified power, a DC-DC converter is employed. This converter continuously maintains the rectified power within the acceptable range for the battery, allowing for smooth charging operations.

If we happen to be utilizing a direct current (DC) source, such as energy derived from a wind farm or solar farm, the need for a rectifier diminishes. However, DC-DC converters remain essential to ensure the battery charging remains within specified limits. This harmonious interplay is facilitated by the Battery Management System (BMS), which oversees and regulates the various components involved in the charging process.

“The Triple Pillars of EV Charging Efficiency!”

Distinct levels of charging are available for electric vehicles, starting with Level 1 charging:

Level I EV Charging: Slow

This is the simplest form of charging that utilizes a basic adapter that can be plugged into any standard 3-pin socket. Typically, these power bricks are provided for free with the vehicle, like the charging adapters that come with mobile phones. This charger is highly portable and convenient to carry around with the vehicle. However, it charges the vehicle at a slower rate. To load 25-30 miles of energy into the battery, this charger may take up to 5 hours. The rated circuit of such charger is maxed 120V delivering 12-15Amps with rated power of.

Level II EV Charging: Fast

These chargers operate on a 240V circuit and offer a significantly higher range of current output, typically ranging from 16 to 80 amps. They do come with an additional cost compared to Level 1 chargers. It is important to note that Level 2 chargers require a dedicated area with proper ventilation, as they generate more heat during operation and require adequate cooling measures. They are immovable once installed.

These chargers can efficiently deliver power and equipped with robust components designed to withstand high loads. Level 2 chargers can load the battery in just an hour with an impressive range of 10 to 80 miles. These chargers are particularly suitable for individuals who have long daily commutes for work or frequently embark on journeys, allowing them to quickly replenish their vehicle’s energy reserves.

These chargers are frequently promoted by OEMs for Homeowners as they have slightly better profit margins attached to them.

Level III – High-Powered Charging (DC Fast Charging): Fastest

This level of charging is not commonly encountered and is typically reserved for specific use cases. High-powered chargers, often found at designated locations like charging stations, car dealerships, or residential parking spots, fall into this category. These chargers are more substantial in size and require ample space for installation.

DC fast charging technology is employed in these chargers, allowing them to rapidly charge electric vehicles. In just 30-40 minutes, these chargers can provide enough power to bring the EV’s battery level up to 80%. One prominent example of Level III chargers is the Ather Grid, Magenta, and Tata Power, which are known for efficiently delivering high-speed charging to EV’s.

Charge Connectors: Shattering the Myth of Simplicity

World of Charging Connectors

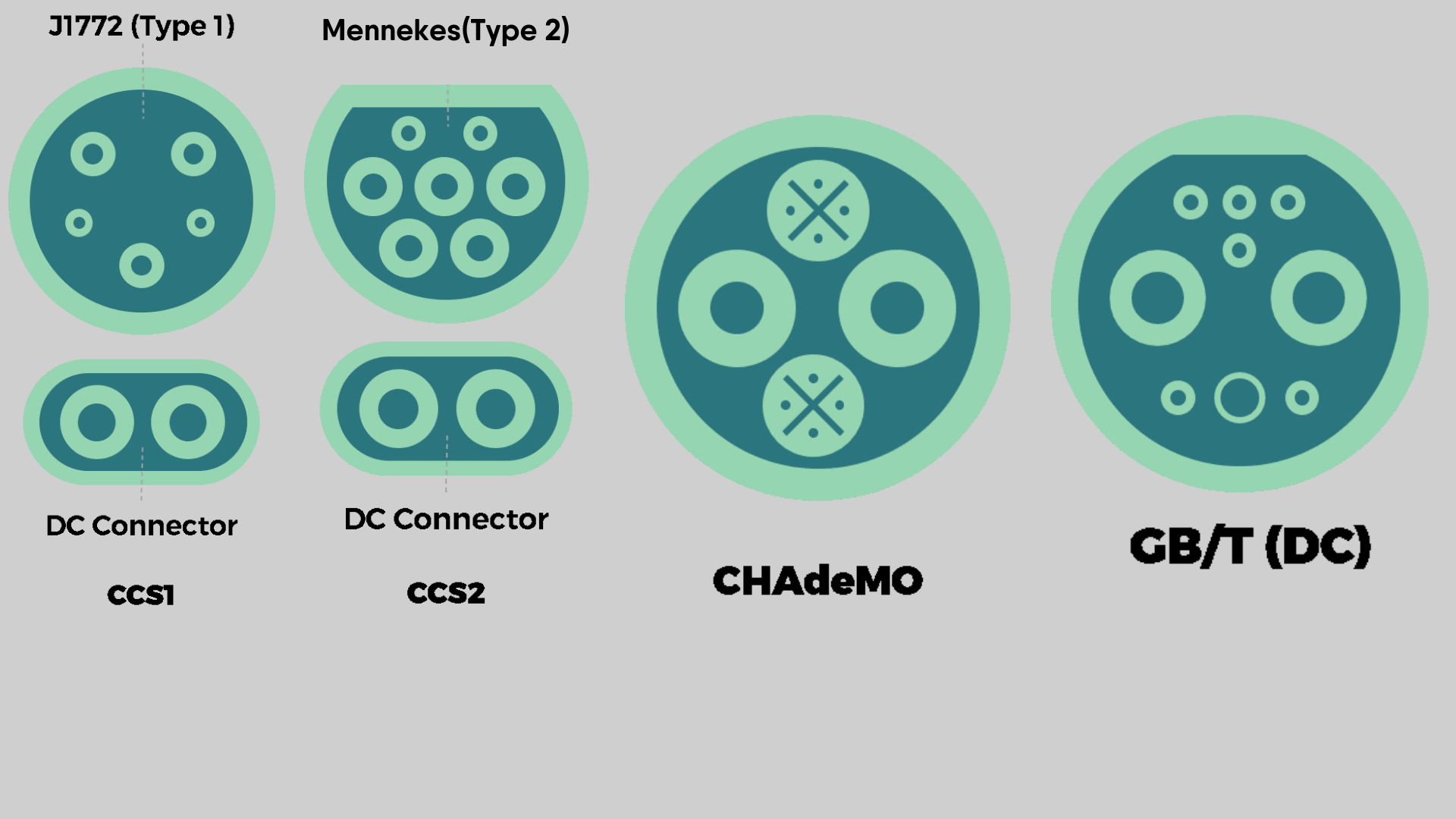

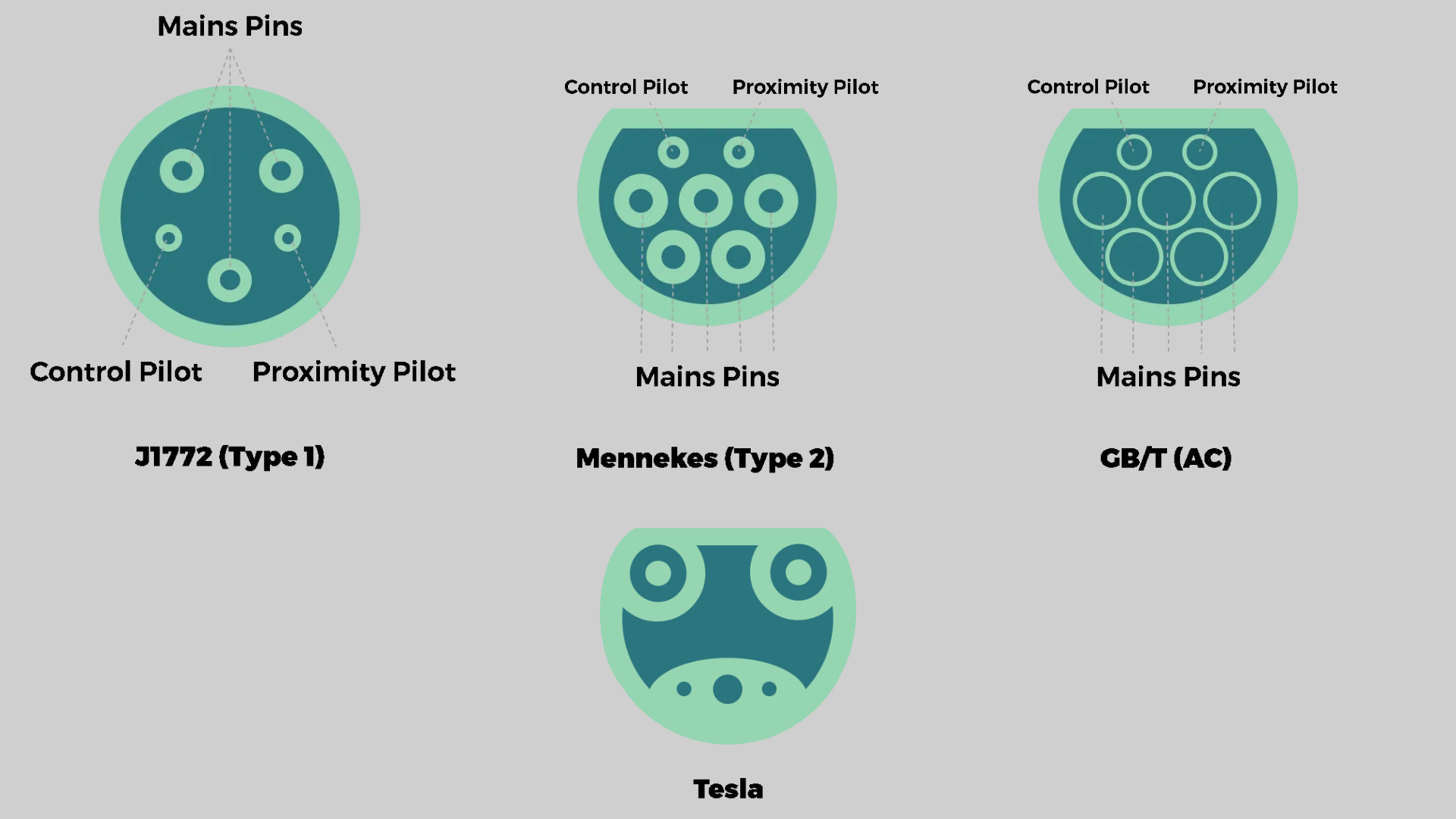

In the realm of EV mobility charging, standardization is yet to reach the level we see in the mobile market with Type C ports. A variety of popular connectors dominate the AC supply landscape, such as SAE J1772 (Type 1) for North America and Japan, Mennekes (Type 2) for the EU region, GB/T for China and GB/T Bharat DC 001 for India.

When it comes to DC supply, different connectors take the stage, including CCS1 for North America, CHAdeMO for Japan, CCS2 from Europe, and GB/T for China and India, In India we are adhering to the Bharat DC 001 standard. While standardization may seem elusive, these charge connectors pave the way for electric mobility, offering compatibility across regions with their unique specifications.

Let us explore the fascinating realm of Ohm’s Law physics in action by delving into the specifications of the Nexon EV Max Battery pack for our calculations.

“The Electrifying Math: Tata Nexon EV Battery Calculation Unveiled!”

The total capacity of the battery pack is an impressive 40.5 kWh, which can be calculated as 40.5 multiplied by 1000W, then further multiplied by 60 and 60 (the total seconds in one hour). This calculation yields a staggering total energy of approximately 145.8 MJ.

The battery pack highlights a remarkable 104s8p configuration, where 104 cells are connected in series within each module, and 8 modules are connected in parallel. This intricate setup creates an electrifying symphony of power.

Each cell operates at a nominal voltage of 3.2V. By multiplying this voltage by the number of cells within one module (104), we arrive at a total nominal voltage of 332.8 volts. The sheer voltage is enough to make one’s pulse race with excitement!

Returning to our earlier discussion of total energy in watt-hours (Wh), we find that it amounts to 40,500Wh. This suggests that the battery architecture operates at an approximate voltage of 400 volts, emphasizing the impressive capabilities of the battery system.

Now, let us turn our attention to determining the time required to charge a single cell within a module. This calculation will give us insight into the total time needed to charge the entire battery. Considering the energy calculation for one cell (2Ah multiplied by 3.2V), we find it to be 6.4Wh. Using a 30-kW adapter, we can charge a single cell in approximately 0.767 seconds, displaying the remarkable speed of charging.

By extrapolating this charging time to the entire vehicle, with an energy capacity of 40,500Wh, and employing the same 30 kW adapter, we can estimate that it will take 1.35 hours to fully charge the battery.

Feel the power, my friend, and bask in the glow of being a charging connoisseur!

To get an EV Charger installed at your location reach out to us at 1C EV Charging.

Talk to our expert about EV Charging, kindly fill in the details below.

Content Writer

harshit@gomassive.org

© 2024 Massive Mobility Private Limited. All rights Reserved